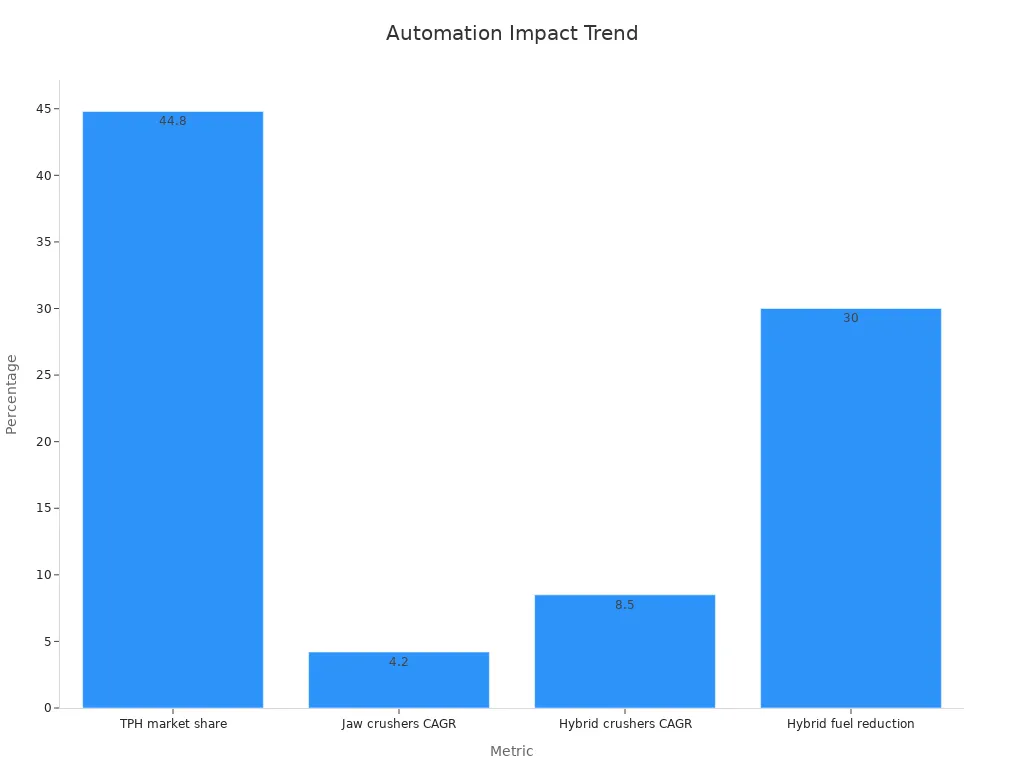

Teknologi komponen crusher terus berkembang di tahun 2025. Perusahaan kini menggunakan otomatisasi pintar, material tahan aus, dan desain hemat energi untuk meningkatkan efisiensi dan daya tahan. Misalnya, pemantauan waktu nyata dan sistem hibrida membantu mengurangi waktu henti dan memangkas penggunaan energi hingga 30%.

| Metrik/Tren | Nilai/Statistik | Dampak terhadap Kinerja Crusher pada tahun 2025 |

|---|---|---|

| Pendapatan penghancur rahang toggle tunggal (2024) | USD 1,8 miliar | Dominasi pasar untuk desain canggih |

| Pangsa segmen kapasitas 100–300 TPH (2024) | 44,8% | Efisiensi bahan bakar dan otomatisasi yang dioptimalkan |

| Penghancur hibrida memperkirakan CAGR | 8,5% | Peningkatan efisiensi energi |

Operator melihat manfaat nyata dengan masa pakai yang lebih lama untuksuku cadang penghancur, biaya lebih rendah untuk mesin penghancur rahang, dan opsi fleksibel untukbagian penghancur kerucut, bagian penghancur dampak, DanBagian penghancur VSI.

Poin-Poin Utama

- Sensor pintar dan otomatisasi membantu mendeteksi masalah sejak dini,mengurangi waktu henti, dan menghemat uang untuk pemeliharaan.

- Material dan pelapis canggihmembuat komponen penghancur bertahan lebih lama, bekerja lebih baik, dan menurunkan biaya penggantian.

- Desain hemat energi dan kontrol kecepatan variabel memangkas penggunaan daya dan mengurangi biaya operasional.

- Komponen penghancur yang modular dan mobile memungkinkan perbaikan cepat, meningkatkan keselamatan, dan menawarkan solusi fleksibel untuk berbagai pekerjaan.

- AI dan peralatan digital memprediksi kegagalan, mengoptimalkan kinerja, dan memperpanjang umur peralatan, meningkatkan produktivitas dan memangkas biaya.

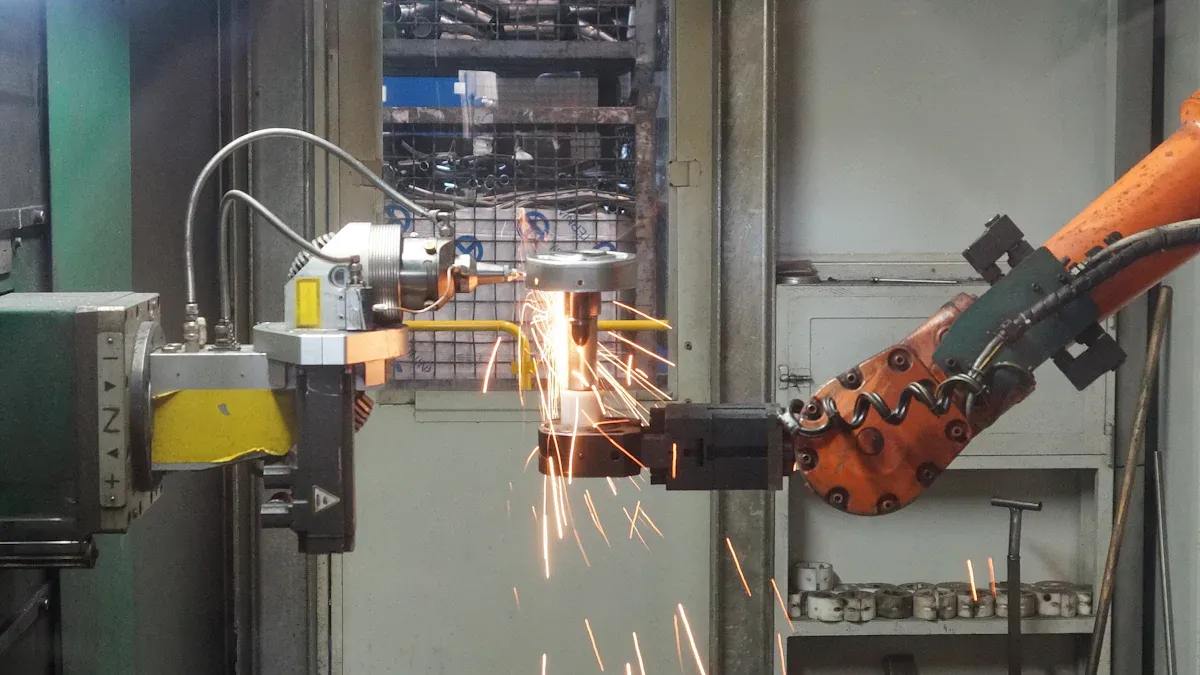

Sensor Cerdas dan Otomatisasi di Bagian Crusher

Pemantauan Waktu Nyata dan Pemeliharaan Prediktif

Sensor pintar sekarang memainkan peran besar dalam menjagabagian penghancurBerjalan lancar. Sensor-sensor ini memantau kondisi peralatan secara real-time. Operator mendapatkan informasi terbaru tentang suhu, getaran, dan keausan secara langsung. Ini membantu mereka mendeteksi masalah sebelum menjadi kegagalan besar. Sistem pemeliharaan prediktif menggunakan analitik data untuk menemukan kesalahan lebih awal. Ini berarti tim dapat memperbaiki masalah sebelum menyebabkan waktu henti.

- Sistem pelumasan otomatis menjadwalkan siklus pelumasan berdasarkan data waktu nyata, yang membantu mencegah kegagalan bantalan.

- Sensor pemantauan kondisi memberikan pembaruan langsung, sehingga operator dapat bertindak cepat.

- Pemeliharaan prediktif mengalihkan perbaikan dari jadwal yang ditetapkan ke pendekatan berbasis kebutuhan, sehingga menghemat waktu dan uang.

- Pemantauan keausan waktu nyata dan kerangka kerja kembaran digital memprediksi keausan alat, mengurangi kerusakan yang tidak terduga.

- Model pembelajaran mendalam dapat memprediksi keausan alat dengan akurasi tinggi, membuat pemeliharaan lebih cerdas.

Alat pintar ini membantu perusahaan memperpanjang umur peralatan dan memangkas biaya pemeliharaan.

Sistem Penyesuaian Otomatis untuk Bagian Crusher

Otomatisasi tidak hanya terbatas pada pemantauan. Banyak mesin penghancur modern menggunakan sistem penyesuaian otomatis. Sistem ini mengubah pengaturan seperti lebar celah atau laju umpan tanpa menghentikan mesin. Operator dapat melakukan perubahan dari panel kontrol atau bahkan dari jarak jauh. Hal ini menjaga mesin penghancur tetap beroperasi secara optimal dan mengurangi kebutuhan akan pemeriksaan manual.

- Powerscreen Pulse, misalnya, memberikan wawasan waktu nyata tentang status mesin, keausan, dan kebutuhan perawatan.

- Fitur seperti GPS langsung, efisiensi bahan bakar, dan pesan kesalahan membantu operator membuat keputusan cepat.

- Akses jarak jauh berarti tim dapat memantau dan menyesuaikan pengaturan dari mana saja.

Studi Kasus: Pengurangan Waktu Henti dengan Smart Crusher Parts

Hasil nyata menunjukkan kekuatan otomatisasi pintar. Peringatan perawatan prediktif pada mesin Caterpillar mengurangi waktu henti hingga 30%. Perusahaan mengalami peningkatan efisiensi operasional sebesar 20% dan menghemat hingga $500.000 setiap tahun. Dasbor waktu nyata membantu merencanakan perbaikan dan menjaga mesin tetap beroperasi lebih lama.

Sensor pintar dan otomatisasimembantu operator menghindari kerusakan yang mahal dan menjaga komponen penghancur bekerja lebih keras dan lebih lama.

Material Tahan Aus Canggih untuk Komponen Crusher

Paduan dan Komposit Generasi Berikutnya

Paduan dan komposit baru mengubah daya tahan komponen crusher. Metal Matrix Composites (MMC) menonjol karena dapat bertahan hingga tiga kali lebih lama dibandingkan material lama. Beberapa komponen, seperti pelapis lengan laba-laba Rock Box, kini menawarkan masa pakai hingga 300% lebih lama. Ini berarti lebih sedikit waktu henti dan lebih sedikit penggantian.Rak pemasangan cekung tingkat lanjutHal ini juga membantu dengan memangkas waktu pemasangan hingga setengahnya, sehingga perawatan menjadi lebih aman dan cepat. Para insinyur menggunakan pemindaian laser 3D untuk melacak keausan dan mengoptimalkan bentuk ruang penghancur. Hal ini dapat menggandakan masa pakai beberapa komponen. Peningkatan ini membuat komponen penghancur lebih tangguh, lebih aman, dan lebih andal.

- Pengujian keausan lapangan menempatkan material pada kondisi pertambangan sesungguhnya, sehingga menghasilkan hasil nyata.

- Paduan yang berbeda, seperti baja karbon dan besi cor putih, menunjukkan perbedaan besar dalam seberapa baik mereka menahan keausan.

- Bahan yang lebih baik berarti biaya yang lebih rendah untuk penggantian, tenaga kerja, dan kehilangan produksi.

- Pemodelan komputer membantu ilmuwan merancang material yang lebih kuat dengan mempelajari kekuatannya dan cara material tersebut pecah.

Pelapis Keramik dan Polimer untuk Bagian Penghancur

Lapisan keramik dan polimer menambahkan lapisan perlindungan tambahan. Lapisan ini membantu komponen mesin penghancur menahan goresan, panas, dan korosi. Lapisan keramik sangat keras dan dapat menangani pekerjaan berat, sementara lapisan polimer lebih ringan dan mengurangi gesekan. Bersama-sama, keduanya membantu komponen mesin penghancur lebih awet dan bekerja lebih baik. Beberapa lapisan baru bahkan membantu menghemat energi dengan mengurangi gaya yang dibutuhkan untuk menghancurkan batu. Ini berarti mesin menggunakan daya lebih sedikit dan dapat beroperasi lebih lama.

- Penguji tipe penghancur rahang khusus menunjukkan bahwa keausan dan penggunaan energi saling terkait erat.

- Lebih sedikit keausan berarti lebih sedikit energi yang terbuang, sehingga penghancur bekerja lebih efisien.

Bahan Bagian Penghancur Tradisional vs. Canggih

| Metrik | Lapisan Penghancur Lanjutan (misalnya, baja mangan Kelas 846) | Liner Tradisional/Kualitas Rendah |

|---|---|---|

| Pakai Hidup | Sekitar 2x lebih panjang | Garis dasar |

| Efisiensi Penghancuran | 35% lebih baik | Garis dasar |

| Optimasi Throughput | Ya | No |

| Pengurangan Konsumsi Daya | Ya | No |

| Efektivitas Peralatan | Ya | No |

Material canggih seperti baja mangan Grade 846 mengandung lebih banyak mangan dan karbon. Keseimbangan ini menghasilkan kekerasan dan ketangguhan yang lebih baik. Material tradisional tidak tahan lama dan membutuhkan penggantian yang lebih sering. Beberapa komposit canggih, seperti polimer yang diperkuat serat karbon, sangat kuat tetapi dapat rapuh dan lebih mahal. Untuk saat ini, pencampuran logam dengan komposit memberikan hasil terbaik untuk komponen crusher.

Memilih material tahan aus yang canggih membantu perusahaan menghemat uang, mengurangi waktu henti, dan mendapatkan lebih banyak manfaat dari suku cadang penghancur mereka.

Inovasi Efisiensi Energi pada Komponen Crusher

Desain Komponen Penghancur Hemat Daya

Produsen sekarang mendesainbagian penghancuruntuk menghemat daya lebih banyak dari sebelumnya. Penghancur kerucut modern menggunakan fitur seperti penggerak frekuensi variabel. Penggerak ini menyesuaikan kecepatan berdasarkan seberapa banyak material yang perlu dihancurkan. Penyesuaian cerdas ini dapat menghemat sekitar 20% penggunaan energi. Beberapa desain baru bahkan menggunakan bantalan levitasi magnetik. Bantalan ini mengurangi penggunaan energi hingga 30% dan membantu komponen lebih awet. Ketika perusahaan memilih penghancur yang tepat untuk pekerjaan tersebut, mereka menghindari pemborosan energi. Menjaga ukuran umpan tetap stabil dan menggunakan komponen berkualitas tinggi juga membantu. Pemeriksaan rutin pada batang impak, liner, dan sabuk menjaga semuanya berjalan lancar dan efisien.

Kiat: Menggunakan penghancur hibrida atau listrik dengan otomatisasi pintar dapat menurunkan tagihan bahan bakar dan listrik lebih jauh lagi.

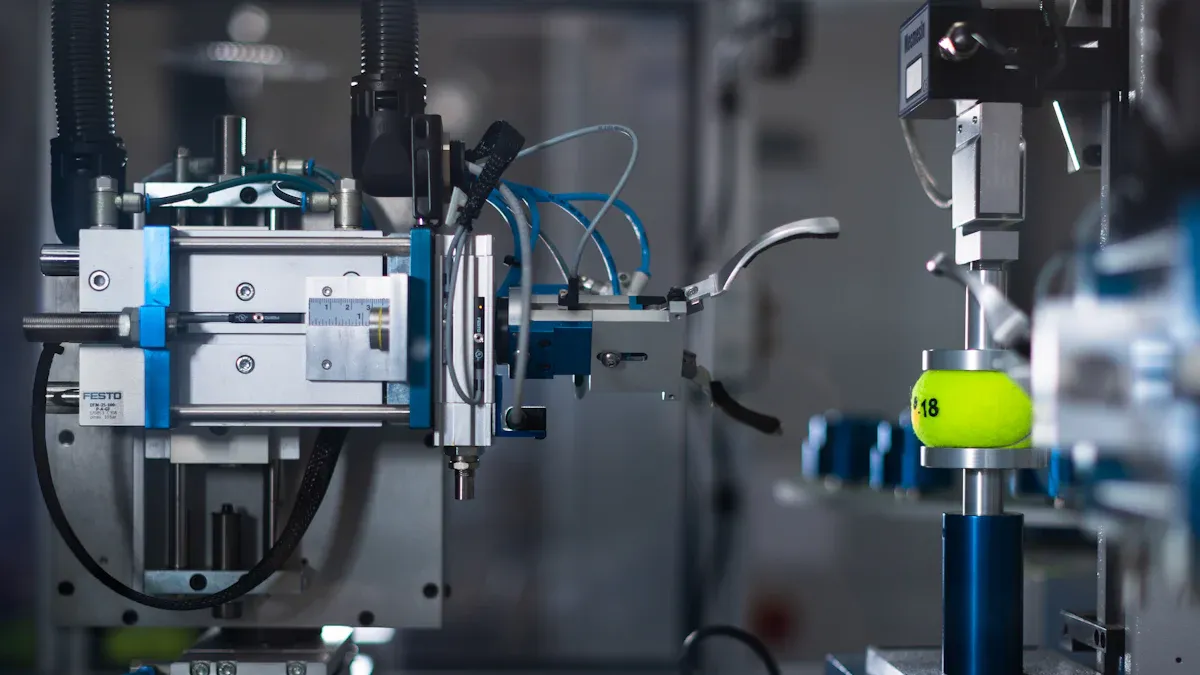

Penggerak Kecepatan Variabel dan Kontrol pada Komponen Crusher

Penggerak kecepatan variabel (VSD) dan sistem kontrol membuat perbedaan besar dalam cara kerja crusher. VSD memungkinkan operator mengontrol kecepatan motor dengan akurasi tinggi. Ini berarti crusher hanya menggunakan daya sesuai kebutuhan. Saat mesin menyala, VSD menurunkan lonjakan listrik, yang melindungi motor dan menghemat energi. Penggerak ini juga membantu mengurangi keausan komponen dan mengurangi limbah. Dengan menghubungkan VSD ke sistem kontrol cerdas, tim dapat memantau penggunaan daya secara real-time dan mendeteksi masalah dengan cepat. Hal ini menjaga crusher tetap beroperasi dengan performa terbaik dan membantu menghindari biaya perbaikan yang mahal.

Dampak Biaya Operasional dari Komponen Penghancur Hemat Energi

Komponen crusher hemat energi membantu perusahaan menghemat biaya setiap hari. Di Clarabelle Mill, mengoperasikan crusher dengan kapasitas desain penuh menurunkan penggunaan energi dan memangkas biaya listrik. Ketika peralatan beroperasi dengan optimal, penalti energi berkurang. Perusahaan yang menggunakan perawatan prediktif menghabiskan biaya perbaikan 20-30% lebih sedikit. Mereka juga melihat peningkatan 10-20% dalam frekuensi ketersediaan mesin mereka. Tabel di bawah ini menunjukkan cara kerja berbagai metode penghematan biaya:

| Metode Analisis Biaya | Keterangan |

|---|---|

| Analisis Biaya Siklus Hidup | Melihat semua biaya selama masa pakai peralatan, termasuk energi dan perbaikan. |

| Total Biaya Kepemilikan | Menjumlahkan biaya tetap dan variabel untuk melihat penghematan jangka panjang. |

| Pemeliharaan Prediktif | Memotong biaya perbaikan hingga 30%. |

| Pemeliharaan yang Dioptimalkan | Meningkatkan penggunaan peralatan dan menghemat lebih banyak uang. |

Memilih komponen penghancur yang hemat energi menghasilkan tagihan yang lebih rendah, waktu henti yang lebih sedikit, dan kinerja yang lebih baik.

Solusi Suku Cadang Penghancur Modular dan Mobile

Suku Cadang Penghancur Modular Ganti Cepat

Sistem modular yang dapat diubah dengan cepat telah mengubah cara tim menanganipemeliharaan penghancurSistem ini memungkinkan pekerja mengganti komponen yang aus dengan cepat, seringkali tanpa alat khusus. Desain modular memungkinkan tim untuk memadupadankan mesin penghancur, penyaring, dan konveyor agar sesuai dengan setiap pekerjaan. Fleksibilitas ini membantu perusahaan menangani berbagai material dan kebutuhan lokasi dengan mudah. Ruang penghancur berkapasitas tinggi meningkatkan produktivitas dan mengurangi kemacetan. Otomatisasi dan pemantauan jarak jauh, seperti telematika Pulse, menjaga mesin tetap beroperasi lebih lama dengan memperingatkan tim tentang masalah sebelum menjadi masalah.

- Komponen modular mengurangi waktu henti selama perbaikan.

- Tim dapat menyesuaikan pengaturan untuk setiap proyek.

- Keselamatan meningkat karena pekerja menghabiskan lebih sedikit waktu untuk menangani komponen berat.

Kiat: Sistem modular juga mendukung unit daya hemat energi, membantu perusahaan memenuhi standar emisi dan tujuan keberlanjutan.

Suku Cadang Mobile Crusher untuk Operasi Fleksibel

Komponen mobile crusher menghadirkan tingkat fleksibilitas baru di lokasi kerja. Komponen ini terpasang pada sasis beroda atau beroda rantai, sehingga tim dapat memindahkannya dengan cepat dari satu lokasi ke lokasi lain. Mobile crusher seringkali mulai bekerja dalam 30 menit hingga beberapa jam setelah tiba. Pengerahan cepat ini menghemat waktu dan biaya. Penghancuran di lokasi berarti lebih sedikit pengangkutan bahan baku, yang menurunkan biaya transportasi dan polusi. Mobile crusher menangani berbagai macam material, mulai dari penambangan hingga daur ulang, dan beradaptasi dengan perubahan kondisi lokasi.

| Fitur | Penghancur Seluler | Penghancur Stasioner |

|---|---|---|

| Mobilitas | Berpindah dengan mudah antar situs | Diperbaiki di satu lokasi |

| Waktu Penerapan | 30 menit hingga jam | Diperlukan pengaturan yang lama |

| Kapasitas | 225-1000 ton/jam | Hingga 2000+ ton/jam |

| Fleksibilitas | Tinggi | Rendah |

| Biaya Pemeliharaan | Lebih tinggi | Lebih rendah |

| Dampak Lingkungan | Transportasi yang dibutuhkan lebih sedikit | Perlu pengendalian debu |

| Jangka hidup | Singkat | Lebih panjang |

Penghancur seluler menggunakansistem rotor dan alat modularTim dapat menyesuaikannya untuk material yang berbeda, yang meningkatkan efisiensi dan memperpanjang umur komponen aus.

Pengurangan Waktu Perawatan dengan Komponen Penghancur Modular

Komponen penghancur modular membuat perawatan jauh lebih cepat. Tim tidak perlu lagi menghabiskan waktu berjam-jam atau berhari-hari untuk perbaikan. Sistem penggantian cepat memungkinkan pekerja mengganti komponen yang aus dalam waktu yang lebih singkat, sehingga mesin tetap beroperasi. Pendekatan ini juga mengurangi penanganan manual, sehingga prosesnya lebih aman dan mudah. Perusahaan mengalami lebih sedikit waktu henti dan biaya tenaga kerja yang lebih rendah. Otomatisasi dan pemantauan jarak jauh membantu tim merencanakan perawatan sebelum kerusakan terjadi.

- Pertukaran komponen yang cepat berarti waktu aktif yang lebih lama.

- Lebih sedikit pekerjaan manual meningkatkan keselamatan dan ergonomi.

- Pemrosesan di tempat mengurangi penundaan transportasi dan perbaikan.

Perusahaan yang menggunakan solusi modular dan mobile melihat keuntungan nyata dalam produktivitas, keselamatan, dan penghematan biaya.

Digitalisasi dan Pemeliharaan Prediktif untuk Suku Cadang Crusher

Analisis Data untuk Kinerja Suku Cadang Crusher

Analisis data kini membantu perusahaan memaksimalkan kinerja peralatan mereka. Dengan menggunakan perangkat digital, tim dapat melacak kinerja mesin penghancur secara real-time. Desain Eksperimen (DoE) memungkinkan para insinyur menguji berbagai pengaturan dan melihat bagaimana perubahan memengaruhi output. Mereka dapat menemukan pola yang terlewatkan oleh metode lama. Misalnya, mereka dapat melihat bagaimana kecepatan dan ukuran celah bekerja sama untuk mengubah kinerja. Tim menggunakan pengambilan sampel belt-cut dan pemantauan proses untuk mengumpulkan data. Hal ini membantu mereka menyesuaikan mesin untuk hasil yang lebih baik. Eksperimen digital memudahkan perencanaan dan peningkatan produksi.

- Insinyur menggunakan persamaan orde pertama dan kedua untuk memodelkan kinerja penghancur.

- Pemantauan berkelanjutan membantu tim memenuhi standar produk dan kebutuhan pasar.

Platform Pemeliharaan Prediktif untuk Suku Cadang Crusher

Platform pemeliharaan prediktif menggunakan data waktu nyata untuk menjaga mesin tetap beroperasi lebih lama. Nukon membangun dasbor untuk Newcrest Mining yang memprediksi kapan harus menggantipelapisAlat ini menggunakan data langsung dan model regresi untuk merencanakan pemeliharaan. Tim tidak lagi menebak-nebak kapan harus memperbaiki komponen. Mereka menerima peringatan sebelum masalah terjadi. Pendekatan ini menggantikan metode manual lama dan mempermudah penjadwalan. Hasilnya adalah perencanaan yang lebih baik dan mesin penghancur yang lebih andal.

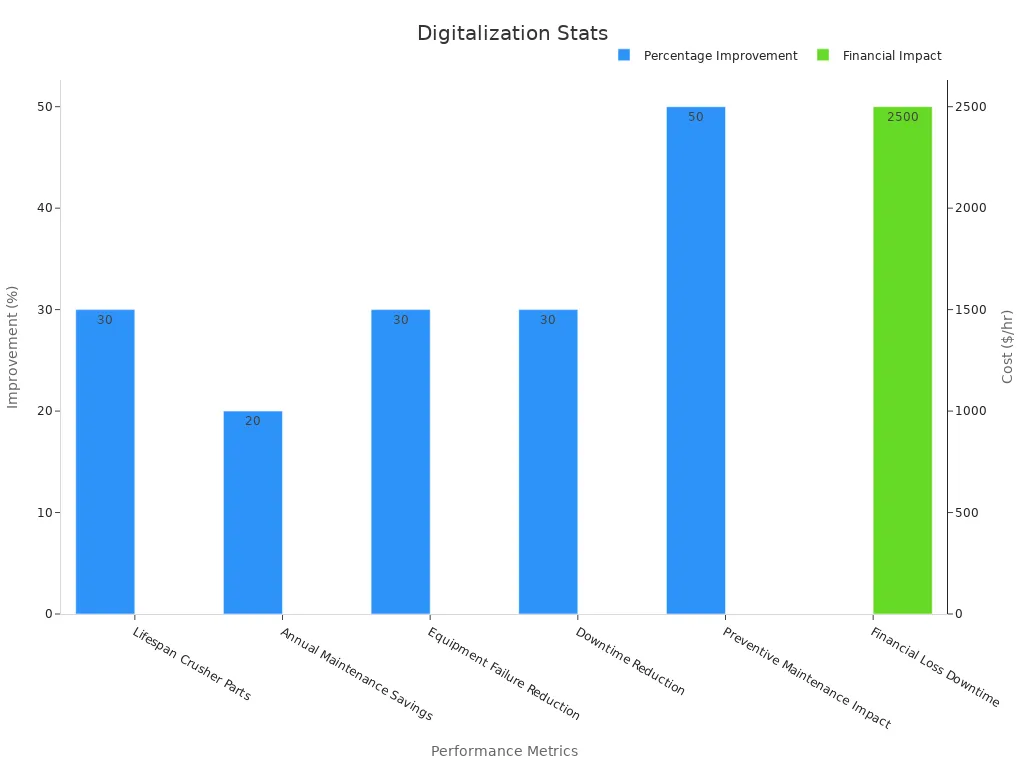

| Metrik Kinerja | Statistik Peningkatan | Deskripsi Dampak |

|---|---|---|

| Perpanjangan masa pakai komponen penghancur | Hingga 30% | Menggunakan material berkualitas tinggi memperpanjang umur komponen, mengurangi frekuensi penggantian. |

| Penghematan biaya pemeliharaan tahunan | Hingga 20% | Suku cadang premium dan perawatan yang dioptimalkan mengurangi biaya perawatan tahunan. |

| Pengurangan kemungkinan kegagalan peralatan | Hingga 30% | Pemeliharaan preventif menurunkan risiko kegagalan, meningkatkan efisiensi operasional. |

| Pengurangan waktu henti | Hingga 30% | Berinvestasi pada suku cadang premium mengurangi waktu henti yang tidak direncanakan secara signifikan. |

| Kerugian finansial akibat penghentian yang tidak direncanakan | Sekitar $2.500 per jam | Menyoroti dampak biaya dari waktu henti, menekankan nilai peningkatan waktu aktif. |

| Dampak pemeliharaan preventif terhadap kegagalan | Diskon hingga 50% | Pemeliharaan terjadwal mengurangi kegagalan mesin, meningkatkan keandalan dan waktu aktif. |

Pemeliharaan prediktif membantu tim menghindari kerusakan yang mahal dan menjaga mesin penghancur bekerja sebaik-baiknya.

Memperpanjang Umur Komponen Crusher dengan Alat Digital

Peralatan digital membantu memperpanjang umur komponen crusher. Perangkat lunak pemeliharaan mengirimkan pengingat dan menyimpan catatan. Hal ini menjaga inspeksi tetap sesuai jadwal dan membantu tim memperbaiki masalah lebih awal. Sensor getaran dan suhu mendeteksi baut yang longgar atau panas berlebih sebelum terjadi kerusakan. Sistem pelumasan otomatis memberikan jumlah gemuk yang tepat, mencegah hingga 75% kerusakan bearing. Peralatan ini mengurangi waktu henti hingga 30% dan menurunkan biaya pemeliharaan hingga 30%. Efisiensi penghancuran dapat meningkat hingga 15% ketika tim menggunakan peralatan digital untuk pemeriksaan rutin. Perusahaan melihat umur peralatan yang lebih panjang dan lebih sedikit kejutan.

Digitalisasi memberi operator kontrol lebih, menghemat uang, dan membuat mesin penghancur beroperasi lebih lama.

Praktik Suku Cadang Crusher yang Ramah Lingkungan dan Berkelanjutan

Bahan Bagian Penghancur yang Dapat Didaur Ulang dan Berdampak Rendah

Banyak perusahaan sekarang memilihbahan yang mendukung prinsip 3RKurangi, Gunakan Kembali, dan Daur Ulang. Mereka merancang komponen penghancur agar lebih awet dan dapat didaur ulang di akhir masa pakainya. Dalam industri baja, teknologi penghancur terak yang baru membantu mengubah limbah menjadi sumber daya berharga. Pendekatan ini mengurangi limbah TPA dan mendukung ekonomi sirkular. Analisis siklus hidup menunjukkan bahwa penggunaan material daur ulang, seperti beton dari limbah konstruksi, menurunkan jejak karbon. Praktik-praktik ini juga mengurangi kebutuhan akan bahan baku baru, yang membantu melindungi sumber daya alam. Tim yang berfokus pada daur ulang dan masa pakai produk yang lebih lama akan menghasilkan lebih sedikit limbah dan biaya yang lebih rendah.

Pembuatan Suku Cadang Crusher yang Hemat Energi

Manufaktur hemat energi mengubah cara pembuatan komponen mesin penghancur. Perusahaan menggunakan otomatisasi dan kontrol cerdas untuk mengurangi penggunaan energi selama produksi. Berikut beberapa fakta penting:

- Penggunaan energi spesifik untuk penghancuran berkisar antara 0,48 hingga 1,32 kWh per ton.

- Optimalisasi dan otomatisasi pakan dapat menurunkan penggunaan energi hingga 10-30%.

- Desain dan lapisan baru membantu mengurangi gesekan, menghemat lebih banyak energi.

- Gesekan dan keausan menyebabkan kehilangan energi yang besar, tetapi teknologi baru dapat menguranginya hingga 30% dalam 20 tahun ke depan.

- Perubahan ini dapat menghemat hingga 550 TWh energi dan mengurangi 290 juta ton CO2 setiap tahun.

Dengan membuat komponen penghancur dengan lebih sedikit energi, perusahaan membantu planet ini dan menghemat uang.

Kepatuhan Lingkungan dalam Teknologi Suku Cadang Crusher

Teknologi suku cadang penghancur modern membantu perusahaan memenuhi peraturan lingkungan yang ketat. Berikut caranya:

- Penghancur sekarang mengurangi volume sisa, membuat daur ulang lebih mudah dan lebih bernilai.

- Mesin menghilangkan hingga 98% cairan bebas dari besi tua, mengurangi limbah berbahaya.

- Sistem briket memanfaatkan kembali cairan limbah, sehingga perusahaan dapat menggunakannya kembali.

- Sistem pengolahan air mendaur ulang air, menurunkan biaya pembuangan dan membantu memenuhi peraturan.

- Penghancur bertenaga listrik dan sistem penekan debu mengurangi emisi dan menjaga udara tetap bersih.

Perbaikan ini membantu perusahaan mematuhi undang-undang lingkungan, mengurangi limbah, dan mendukung masa depan yang lebih bersih.

Integrasi AI dan Pembelajaran Mesin di Bagian Crusher

Prediksi Kegagalan Berbasis AI untuk Komponen Crusher

AI sekarang membantu tim memprediksi kapanbagian penghancurmungkin gagal. Sistem pintar memantau tanda-tanda seperti getaran, suhu, dan perubahan tekanan. Mereka menggunakan data ini untuk mendeteksi masalah sebelum menyebabkan kerusakan. Misalnya, Sistem Kontrol Penghancur Pintar SBM di pabrik bijih besi Kanada memberikan dampak besar. Sistem menyesuaikan pengaturan secara real-time dan melakukan pemeliharaan terjadwal sebelum kegagalan terjadi. Hal ini menghasilkan peningkatan throughput sebesar 22%, 40% lebih sedikit waktu henti, dan penghematan energi sebesar 15%. Operator mempercayai perangkat AI ini untuk menjaga mesin beroperasi lebih lama dan menghindari kejutan yang merugikan.

| Metrik Kinerja | Peningkatan yang Diatribusikan pada Integrasi AI |

|---|---|

| Peningkatan Throughput | Peningkatan 22% (dari 550 TPH menjadi 670 TPH) |

| Pengurangan Waktu Henti | 40% lebih sedikit kejadian downtime |

| Penghematan Energi | Pengurangan konsumsi energi sebesar 15% |

| Perpanjangan Umur Komponen | Umur pakai komponen yang aus 15–20% lebih panjang |

| Frekuensi Penggantian Liner | Pengurangan 35% di tambang kromit Turki |

Prediksi kegagalan berbasis AI berarti lebih sedikit dugaan dan lebih banyak waktu aktif untuk setiap operasi.

Optimasi Proses Otomatis pada Komponen Crusher

Pembelajaran mesin kini membantu para crusher bekerja lebih cerdas, bukan lebih keras. Kontrol otomatis menyesuaikan laju dan pengaturan umpan untuk menjaga proses tetap stabil. Ini berarti ukuran produk yang lebih konsisten dan kualitas yang lebih baik. Tim tidak perlu lagi memperhatikan setiap detail. Sistem menemukan cara terbaik untuk menjalankan crusher dan mendeteksi masalah sejak dini. Data real-time membantu operator membuat keputusan cepat. Perawatan bergeser dari memperbaiki masalah setelah terjadi menjadi menghentikannya sebelum terjadi.

| Metrik Efisiensi | Deskripsi Perbaikan |

|---|---|

| Konsumsi Energi | Pengurangan hingga 30% tergantung aplikasi |

| Masa Pakai Komponen Aus | Peningkatan masa pakai komponen aus dua hingga empat kali lipat |

| Waktu aktif | Peningkatan waktu aktif karena lebih sedikit pergantian dan pemberhentian |

| Konsistensi Produk | Ukuran produk yang lebih konsisten karena otomatisasi adaptif |

Optimalisasi otomatis memungkinkan tim meningkatkan kinerja tanpa mengeluarkan biaya lebih banyak untuk peralatan baru.

Potensi Masa Depan AI dalam Teknologi Suku Cadang Crusher

Masa depan AI di bidang komponen penghancur tampak cerah. Para ahli memperkirakan pasar penghancur batu akan tumbuh dari $5,2 miliar pada tahun 2024 menjadi $8,3 miliar pada tahun 2033. Otomatisasi berbasis AI, pemeliharaan prediktif, dan pemantauan waktu nyata akan mendorong pertumbuhan ini. Perangkat baru seperti visi komputer dan robotika akan membantu tim bekerja lebih cepat dan lebih aman. Pembelajaran mesin akan terus meningkatkan kinerja penghancur, menjadikannya lebih efisien dan andal.

- Pasar diperkirakan tumbuh pada CAGR 6,2% dari tahun 2026 hingga 2033.

- Integrasi AI akan terus menurunkan biaya dan waktu henti.

- Perusahaan akan menggunakan lebih banyak data untuk membuat pilihan cerdas dan tetap unggul.

Seiring terus berkembangnya AI, komponen penghancur akan menjadi lebih tahan lama, efisien, dan mudah dikelola.

Teknologi komponen penghancur terus berkembang. Perusahaan kini menggunakan peralatan pintar, material yang lebih baik, dan desain hemat energi. Perubahan ini membantu tim bekerja lebih cepat dan menghemat uang. Perubahan ini juga membuat komponen penghancur lebih awet dan membantu planet ini. Siapa pun yang ingin tetap terdepan di bidang ini perlu memperhatikan tren ini. Ide-ide baru dalam komponen penghancur akan terus membentuk industri ini di tahun-tahun mendatang.

Tanya Jawab Umum

Apa manfaat utama menggunakan komponen penghancur pintar?

Cerdasbagian penghancurMembantu tim mendeteksi masalah sejak dini. Mereka mengurangi waktu henti dan menghemat biaya perbaikan. Operator mendapatkan informasi terkini secara real-time, sehingga mereka dapat memperbaiki masalah sebelum menjadi masalah besar. Komponen-komponen ini juga membantu mesin lebih awet.

Bagaimana material canggih meningkatkan kinerja komponen penghancur?

Bahan canggihPaduan dan pelapis khusus membuat komponen crusher lebih tangguh. Komponen ini lebih tahan aus dan panas dibandingkan material lama. Ini berarti komponen lebih awet dan lebih sedikit membutuhkan penggantian. Tim menghabiskan lebih sedikit waktu dan uang untuk perawatan.

Apakah bagian penghancur modular mudah dipasang?

Ya, komponen penghancur modular menggunakan sistem penggantian cepat. Pekerja dapat menggantinya dengan cepat, seringkali tanpa alat khusus. Hal ini membuat pemasangan lebih aman dan mudah. Tim menghabiskan lebih sedikit waktu untuk perbaikan dan mesin dapat beroperasi kembali dengan cepat.

Apakah komponen penghancur yang ramah lingkungan lebih mahal?

Komponen penghancur ramah lingkungan terkadang sedikit lebih mahal pada awalnya. Seiring waktu, komponen ini menghemat biaya karena lebih awet dan mengurangi limbah. Banyak perusahaan menganggap penghematan jangka panjang dan manfaat lingkungan sepadan dengan investasinya.

Waktu posting: 14-Jun-2025